Small tomato paste & ketchup & Sauce production line video ( this line just

Small tomato paste & ketchup & Sauce production line video ( this line just

need a very small price budget to buy it )

Final tomato paste pic

Big tomato paste & ketchup & Sauce production line video

1.The tomato paste/sauce/ketchup production line is an automated equipment system .

It mainly includes cleaning, crushing, preheating,

pulping, concentration, sterilization, aseptic filling and other major processes to achieve a

complete production process from raw materials to finished products.

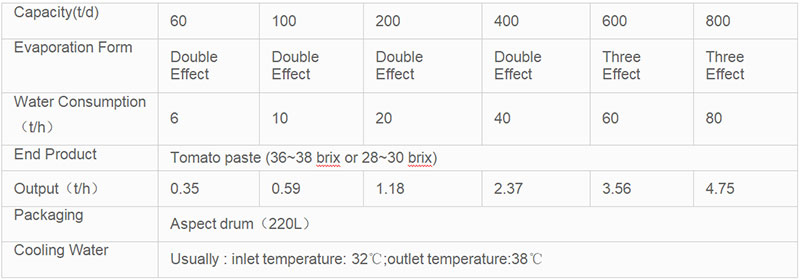

Big Line Producing capacity: 3-40t/h

Small Line Producing capacity:200-500kg/h

The tomato paste brix can be 28%, 30%, 32%, 36% ,38%.

2.Small Scale Tomato Paste/sauce/ketchup Production Line process pic.

welcome you to buy this line from us , thank you .

3. Big Scale Tomato Paste/sauce/ketchup Production Line Process pic.

welcome you to buy this line from us , thank you .

4. Packaging production line pic for tomato paste /sauce / ketch up

(canned pack , sachet pack,bottle pack , jar glass pack) process.

welcome you to buy this line from us , thank you .

1.Our proud production line

2.Focus on tomato paste/sauce/ketchup production line over 20 years

3.We provide you Lifetime after-sales service

4.Turnkey solution for you , save your time

5.Use world brand accessories

6.Smart production line

7.Your needs first

8.Advanced Italian technology, meeting European standards

9. Low-temperature vacuum evaporation technology reduces flavor and nutrient loss

10. Fully automatic PLC control system

The Packaging Drum for the final product - tomato paste (made from big line)

Below are the machines for big tomato paste /sauce line .

1.First : use bubble washing machine(as below pic) to wash the raw tomato

2.Second : then the tomato going to the sorting machine(as below pic),the worker will take out

2.Second : then the tomato going to the sorting machine(as below pic),the worker will take out

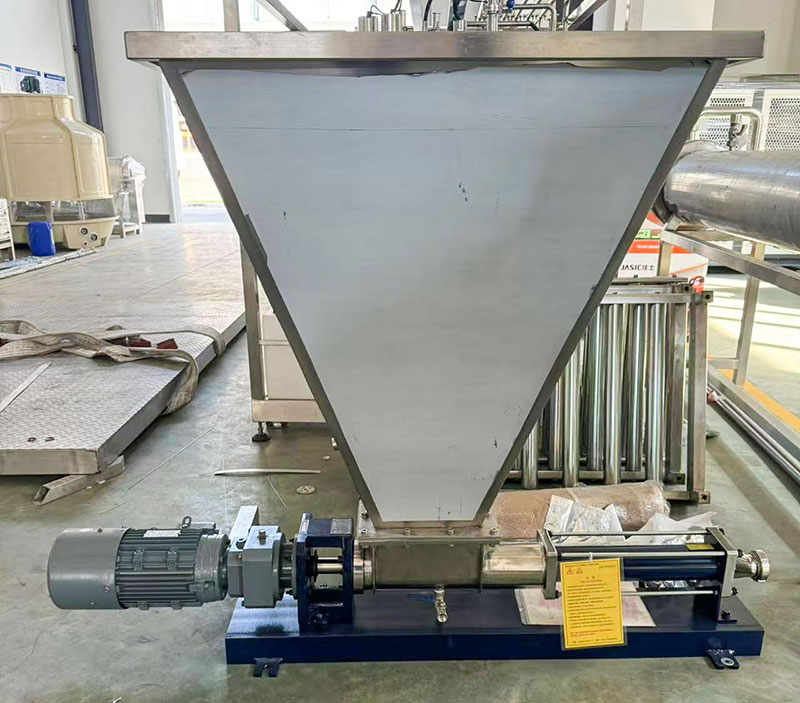

the rotten tomato . 3.Then tomato will going to the screw pump or the elevator (as below pic)

3.Then tomato will going to the screw pump or the elevator (as below pic)

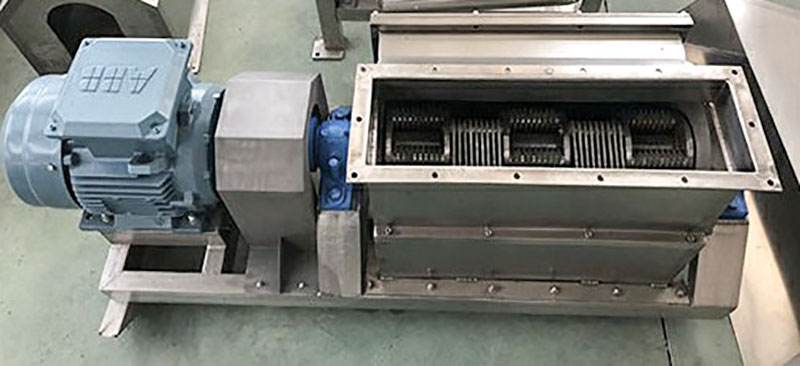

4.Then the tomato going to the hammer crusher(as below pic)

, The tomatoes will be fully crushed

4.Then the tomato going to the hammer crusher(as below pic)

, The tomatoes will be fully crushed 5.Then the crushed tomato go to the preheating machine(as below pic)

5.Then the crushed tomato go to the preheating machine(as below pic)

6.Then tomato going to the pupling machine (as below pic)

6.Then tomato going to the pupling machine (as below pic)

7.The the tomato pulp will going to the evaporator (as below pic)

, the tomato pulp

7.The the tomato pulp will going to the evaporator (as below pic)

, the tomato pulp

will be concentrated 8.After evaporation , the tomato pulp become the tomato paste ,then the tomato paste

8.After evaporation , the tomato pulp become the tomato paste ,then the tomato paste

will going to the UHT sterilizer machine (as below pic)

. 9.After sterilization , the tomato paste will be filled into a bag by the aseptic filling machine

9.After sterilization , the tomato paste will be filled into a bag by the aseptic filling machine

(as below pic)

Below are the notice for set up the big tomato paste line

1.You need hire a professional manage team for the tomato paste/sauce/ketchup producing ,

and the factory director should have at least 3 years experience in

tomato paste producing industry.

2.The factory building can be made of steel structure and the height of the factory building is

higher than 6m

3.Think about the harvest time of your local tomato, and usually it will need 6 months to make

this line works ( 3 month of manufacturing the line, 1 month of logistics time,

2 month of installation and commissioning)

4.For middle class line , it usually need 10-20 workers

5.You should have a good marketing team and selling channel for sell your paste

6.Maybe you can got the loan from your local bank base on this tomato paste production line.

7.You need a lab for this line , the lab include Titimeter, refractometer, incubator, microscope,

centrifuge, sugar meter, etc

8.You need have enough cash to buy the raw tomato for producing

9.If your local government has relevant support policies, you can seek financial support from

your local government government.

10.The price of 36/38 brix tomato paste in China is around 1500 usd ( at Year 2024)

11.8 ton of raw tomato can make 1 ton of 36/38 brix tomato paste

12.This production line requires a boiler, which is usually fueled by natural gas.So your place

better have the natural gas , if not , please let us know ,we will think the other type of boiler.

1.Dongtai Championship Machinery Technology Co., Ltd. is a high-tech enterprise focusing on

tomato paste/sauce/ketchup & juice and pulp processing equipment and line.

2.We are committed to providing efficient, energy-saving and intelligent juice and pulp

production line solutions for the global fruit and vegetable processing industry, covering the

whole process equipment such as cleaning, crushing, extracting, filtering, sterilization,

concentration, aseptic filling, etc.

3.With many years of technical accumulation and market experience, we have mastered

advanced technologies and processes at home and abroad. The company undertakes

business scope including various single-machine equipment and turnkey engineering

projects. We look forward to the opportunity to serve you.

1.We will provide a one-year warranty period.

2.Within this one-year period, we will provide accessories free of charge and offer technical

consultation services free of charge.

3.In case of problems that cannot be solved, our engineers will provide on-site service .

4.After one year, for the above-mentioned services, we will only charge the cost.

Q1: What information is required to obtain the quotation materials?

Q1: What information is required to obtain the quotation materials?

A1:the producing capacity ,and the final product's brix

Q2: Is it convenient for me to visit your company for an inspection?

A2: Of course, we warmly welcome you to visit our company at any time. Our

company is close Shanghai International Airport, and the transportation

is very convenient.

Q3: If we have problems when using your machine, what should we do?

A3: If you have any problem, just contact us, we will help you to solve it. And if necessary,

we will arrange our engineers to help you in your country.

Q4: What's your delivery time?

A4: It takes approximately 90 days(for big line) from the receipt of the deposit to the

completion of the whole line manufacturing. Name:Lucky Gee

Name:Lucky Gee

Whatsapp: +8615195184730

Wechat: +8615195184730

Email: franklin1988999@gmail.com

Address:No.1 Gongye Avenue ,Liangduo Town, Dongtai City,

Jiangsu Province,China