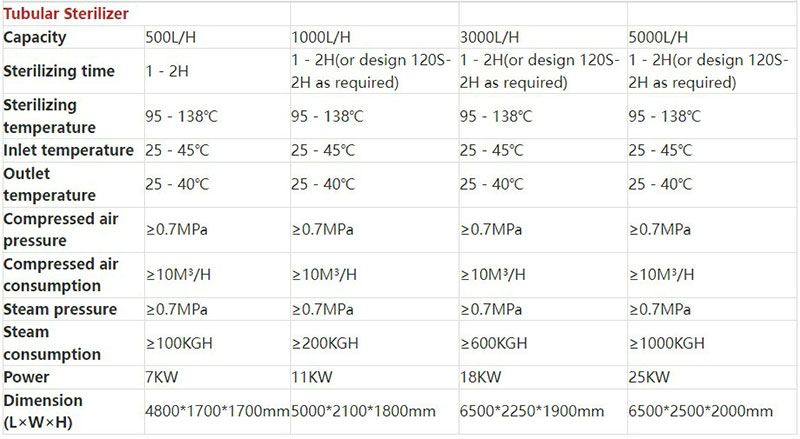

Our proud product -Tubular Sterilizer pic ( use for juice and milk and beverage )

Our proud product -Tubular Sterilizer pic ( use for juice and milk and beverage )

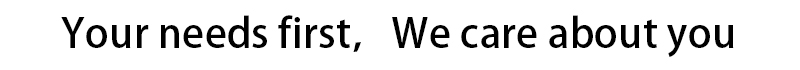

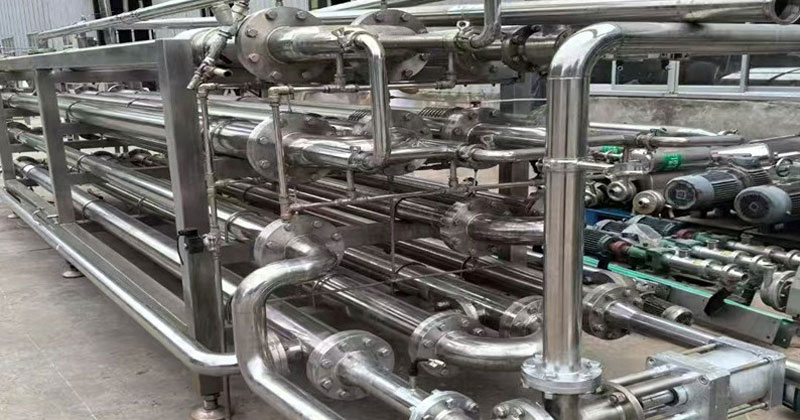

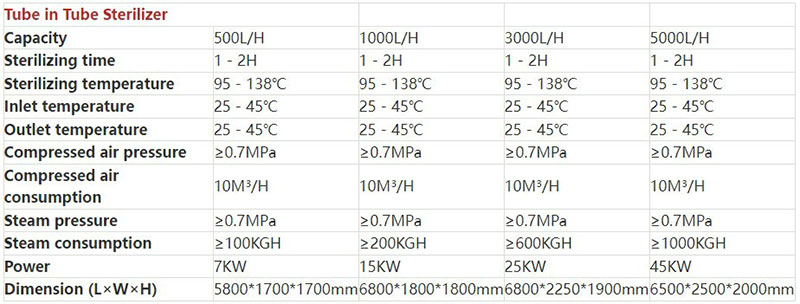

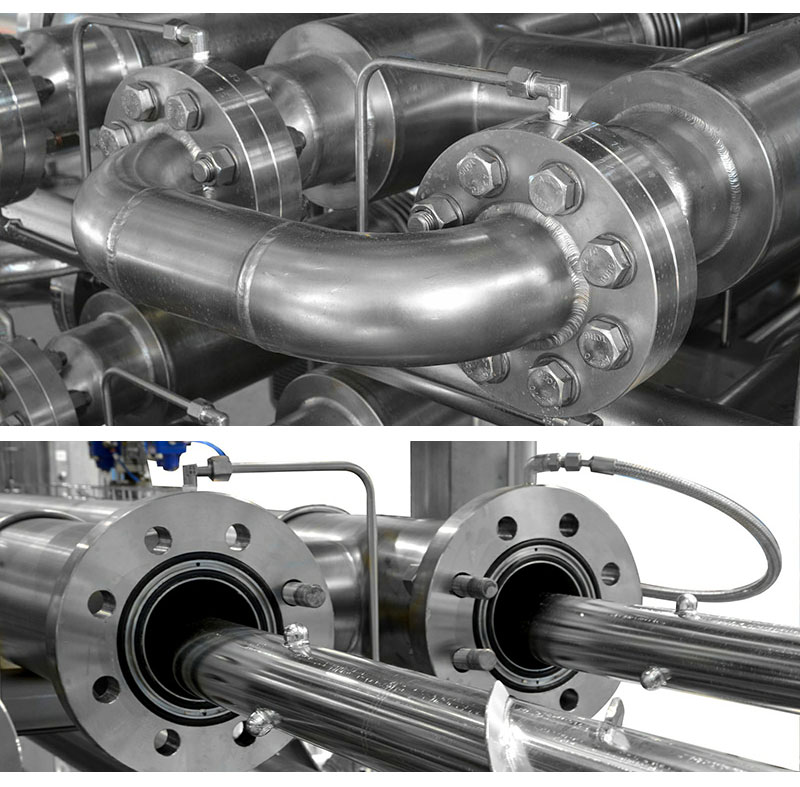

Our proud product -Tube in Tube Sterilizer pic( use for jam, concentrated juice,

Our proud product -Tube in Tube Sterilizer pic( use for jam, concentrated juice,

pulp,syrup etc.)

1.The sterilization parameters can be flexibly set on the touch screen

2.After setting the sterilization parameters, start with one button and run automatically

3.Small temperature deviation and stable operation

4.With heat recovery device, high heat exchange efficiency

5.No manual operation is required in the production process

6.Built-in CIP and SIP systems

7.Online linkage control of front-end equipment and rear-end equipment

8.PLC (programmable logic controller) and touch screen are both Siemens brands

9.steam valve is selected from British Spiraxsarco brand

10.material pump adopts German Netzsch brand

Instant sterilization of fluid food materials at high temperature to achieve the purpose of

Instant sterilization of fluid food materials at high temperature to achieve the purpose of

commercial sterility.It is not only applicable to conventional materials such as fruit juices,

milk, tea beverages, syrups, and fruit purees. At the same time, it is also widely used

for neutral materials such as plant proteins.

Usually ,we use BIB aseptic filling machine or BID aseptic filling machine or full automatic

aseptic filling machine to connect with the sterilizer . after sterilizing , the raw material

will be filling into a bag , and this process is be done by the aseptic filling machine.

Our proud product - BIB aseptic filling machine & BID aseptic filling machine

For continuous sterilization of milk, fruit juice, honey, soy sauce or similar products

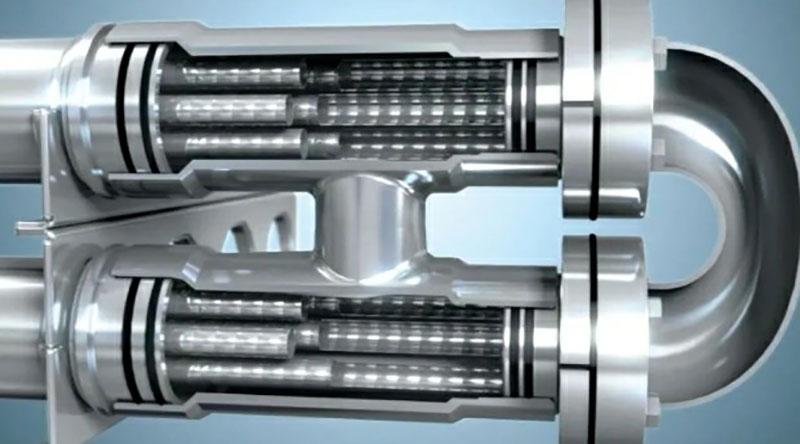

1. Preheating and Heat Exchange

After entering the equipment via a pump, the material is first preheated to approximately 55°C

in the hot and cold material heat exchange unit before entering the high-temperature heat

exchange zone.

2. High-Temperature Sterilization

The material is sterilized by maintaining a high temperature of over 120°C in a tubular heat

exchanger for 3-15 seconds (the specific temperature and time vary depending

on the material).

3. Rapid Cooling

After sterilization, the material is rapidly cooled to approximately 45°C in a cooling unit,

preserving the product's flavor and nutritional content.

Dongtai Championship Machinery Technology Co., Ltd. is a high-tech enterprise focusing on

juice and pulp processing equipment and line.

We are committed to providing efficient, energy-saving and intelligent juice and pulp

production line solutions for the global fruit and vegetable processing industry, covering the

whole process equipment such as cleaning, crushing, extracting, filtering, sterilization,

concentration, aseptic filling, etc.

With many years of technical accumulation and market experience, we have mastered

advanced technologies and processes at home and abroad. The company undertakes

business scope including various single-machine equipment and turnkey engineering

projects. We look forward to the opportunity to serve you.

We will provide a one-year warranty period. Within this one-year period, we will provide

accessories free of charge and offer technical consultation services free of charge.

In case of problems that cannot be solved, our engineers will provide on-site service .

After one year, for the above-mentioned services, we will only charge the cost.

Q1: What information is required to obtain the quotation materials?

Q1: What information is required to obtain the quotation materials?

A1: First of all, we need to know what the raw materials are. Secondly, what is the

processing capacity per hour . Thirdly, are there any special requirements for the

inlet temperature of the materials, the sterilization temperature, the sterilization time,

and the outlet temperature of the materials? Once we have this information,

we can provide the technical parameters and the quotation.

Q2: Is it convenient for me to visit your company for an inspection?

A2: Of course, we warmly welcome you to visit our company at any time. Our

company is close Shanghai International Airport, and the transportation

is very convenient.

Q3: Will you send people to our site for installation and debugging? And conduct training

for our workers.

A3: The connection and operation of our equipment are very simple. You can start it with

just one button after setting the parameters. We will mark the pipe connection points.

The instruction manual can solve all problems, and we also provide online guidance.

If it is really necessary for our engineers to go there, we will make the arrangements.

Q4: If we have problems when using your machine, what should we do?

A4: If you have any problem, just contact us, we will help you to solve it. And if necessary,

we will arrange our engineers to help you in your country.

Q5: What's your delivery time?

A5: It takes approximately 50 days from the receipt of the deposit to the completion of the

equipment manufacturing. Name:Lucky Gee

Name:Lucky Gee

Whatsapp: +8615195184730

Wechat: +8615195184730

Email: franklin1988999@gmail.com

Address:No.1 Gongye Avenue ,Liangduo Town, Dongtai City,

Jiangsu Province,China