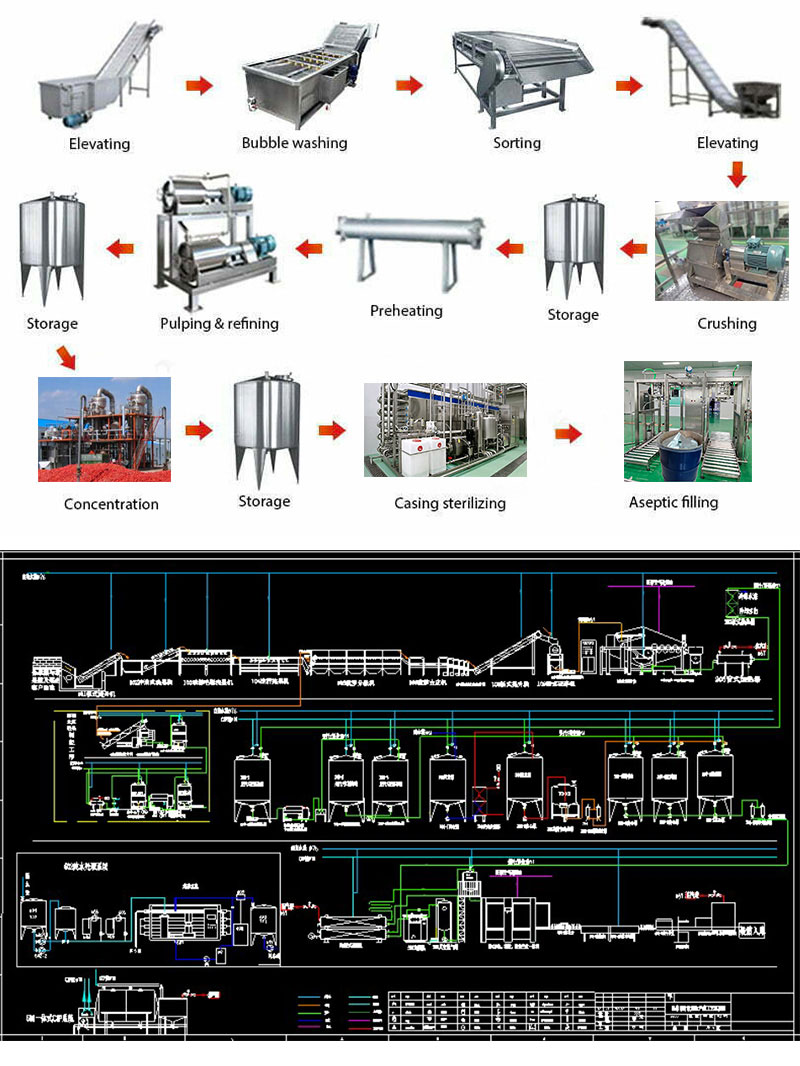

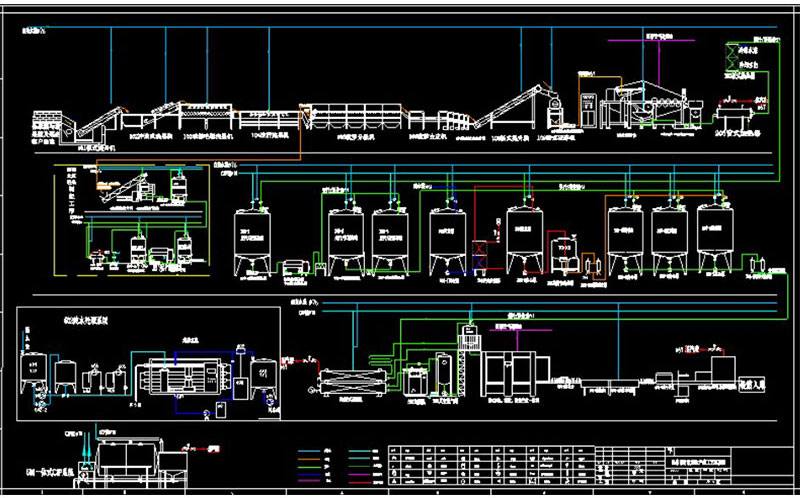

1. Preheating and Heat Exchange

After entering the equipment via a pump, the material is first preheated to approximately 55°C

in the hot and cold material heat exchange unit before entering the high-temperature heat

exchange zone.

2. High-Temperature Sterilization

The material is sterilized by maintaining a high temperature of over 120°C in a tubular heat

exchanger for 3-15 seconds (the specific temperature and time vary depending

on the material).

3. Rapid Cooling

After sterilization, the material is rapidly cooled to approximately 45°C in a cooling unit,

preserving the product's flavor and nutritional content.

Welcome you to contact us

Name:Lucky Gee

Whatsapp: +8615195184730

Wechat: +8615195184730

Email: franklin1988999@gmail.com

Address:No.1 Gongye Avenue ,Liangduo Town, Dongtai City,

Jiangsu Province,China